BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,588

- Name

- Matt w.

Booo!I'm more of a dog person.

Booo!I'm more of a dog person.

Where can I get the coil pack? Psi is crazySounds like it needs a tune up. ( new coil packs and plugs/wires and clean mass airflow sensor. I’ve replaced cats that have been cherry red in 3/4 ton 6.0 vortec pickups due to misfire. All the Unburned fuel toasts the cats and the rapid cool down will also Crack the insides along with the extreme heat. Also determine that your thermostat is not stuck open. engine would be using more fuel to make up temperature.

Amazon $36 looks just like itSounds like it needs a tune up. ( new coil packs and plugs/wires and clean mass airflow sensor. I’ve replaced cats that have been cherry red in 3/4 ton 6.0 vortec pickups due to misfire. All the Unburned fuel toasts the cats and the rapid cool down will also Crack the insides along with the extreme heat. Also determine that your thermostat is not stuck open. engine would be using more fuel to make up temperature.

The lines look ok. I just installed a fuel pressure gauge and it’s 32psi at the fuel manifold. The manual says should be 41-47 psi. I ran the machine with the fuel gauge the engine ran fine for fuel pressure held steady at 32 psi. The machine started to bog as usual after 15 min the fuel pressure held steady at 32 psi. Video attached of the boggingHave you checked your fuel lines and clamps? A clamp could be loose or a small crack that would allow air into the line. Initially your line would be full of fuel but after running it for a while it can't keep up with demand and begins sucking air.

The bogging starts as soon as the thermostat opens .

Is that a zenith engine? If so, I’m certain they can helpUpdate I found that some forklifts use same engine. Psi suggested that they may be able to help since no hydramaster dealer in my area could work on it. They replaced the fuel pump, o2 sensor and fuel filter but still same issue. I need help any suggestions would be appreciated. The bogging starts as soon as the thermostat opens .

This part is not the correct part for the Titan 875.

I was able to pull codes by using the mail lightMaybe check the coolant temperature sensor. (front of engine in head...it is in the loop even with the thermostat closed afaik but I guess worth checking.)

What do the plugs look like? Lean?

Does it have a MIL? Did the forklift shop scan for codes?

I installed a coil pack and set of wires and it’s looks like that did it.

I told you that in post #2I installed a coil pack and set of wires and it’s looks like that did it.

Thanks for kind words AJ it’s been a pleasure hopefully it’s finally fixed.Update the coil pack and wires helped but either an additional or new problem. While before the engine seems to have been missing or bogging ( not the case now) it now runs a minute or two and then starts to stumble like out of fuel. It does this for a bit them works itself out . Does this every time you start it . It actually ended I up giving an 1156 fuel rail error code. I disconnected both o2 sensors and it runs fine. I am still working on this it may be some leaking fuel injectors. I have orders some to see if it clears up. I will say that gene from cleaners connection in Littlerock has really been a ton of help the guy has bent over backwards to help me out. I can’t say enough about these guys . I know how quick folks are to put a bad review or complain but I can’t say enough of how much this guy gene knows about truckmounts. Hydramaster actually sent me to him when they could not figure it out.

Did you ever find out where to get parts for that engine. I think my new to me thermal wave 2 has that same engine and I might need parts in the future.I will cal Robert at Dixie Monday and see if they might have any idea. The 1.6 l Vortec on these units is no longer in production and the ones available are high. Psi produces them and you need a computer diagnostics to read the computer. Hopefully they have the right equipment to diagnose and not just throw parts at it.

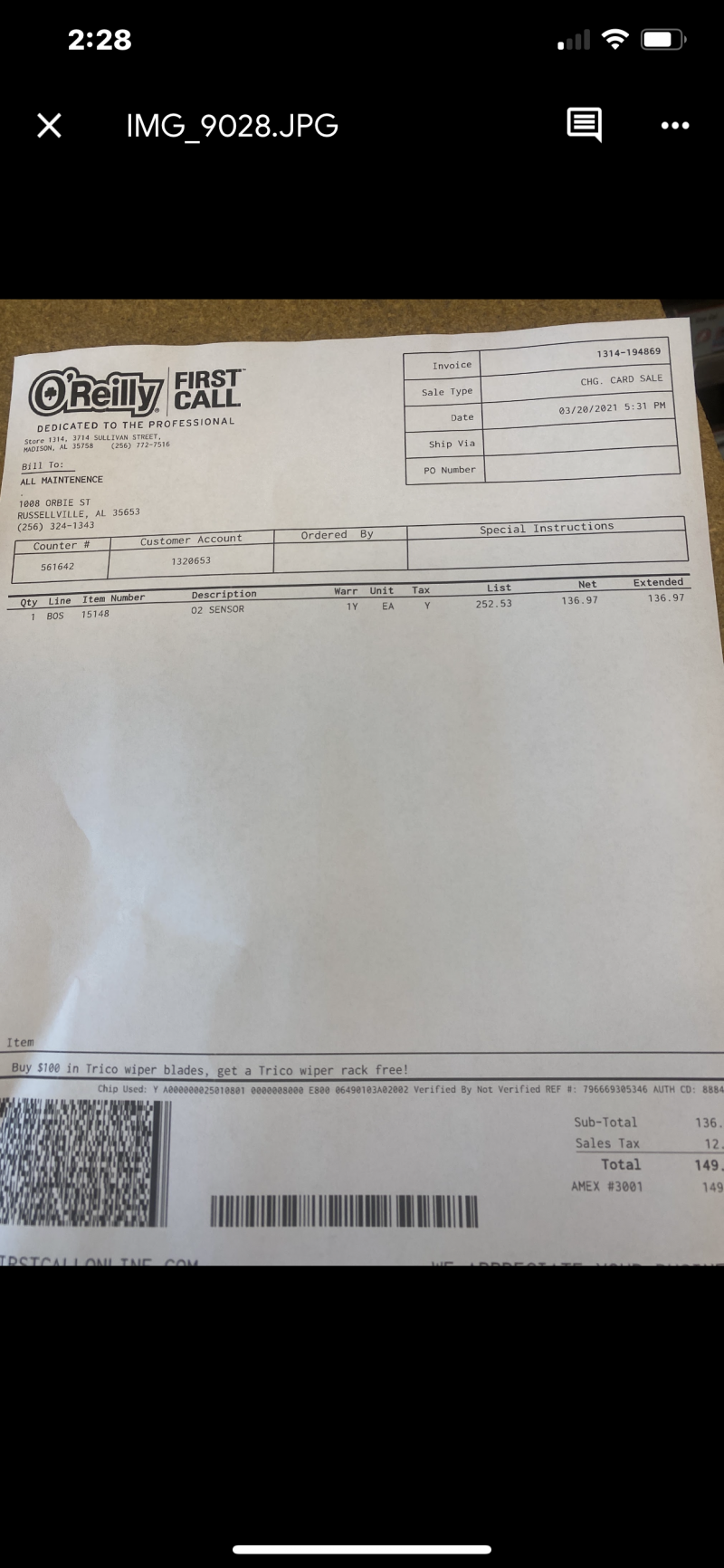

I am still having trouble but have a work around. Btw I also have a Thermalwave 11 . Psi engine for parts but pm me if you need some parts numbers do Orilies cross over . But if you run into any problems the guys at cleaners connection (gene) have been a life saver. My problem looks to be an o2 sensor and ecm. Tons of trouble shooting and actually was able to get the computer diagnostics cable to connect to my laptop and see all operating stuff .Did you ever find out where to get parts for that engine. I think my new to me thermal wave 2 has that same engine and I might need parts in the future.

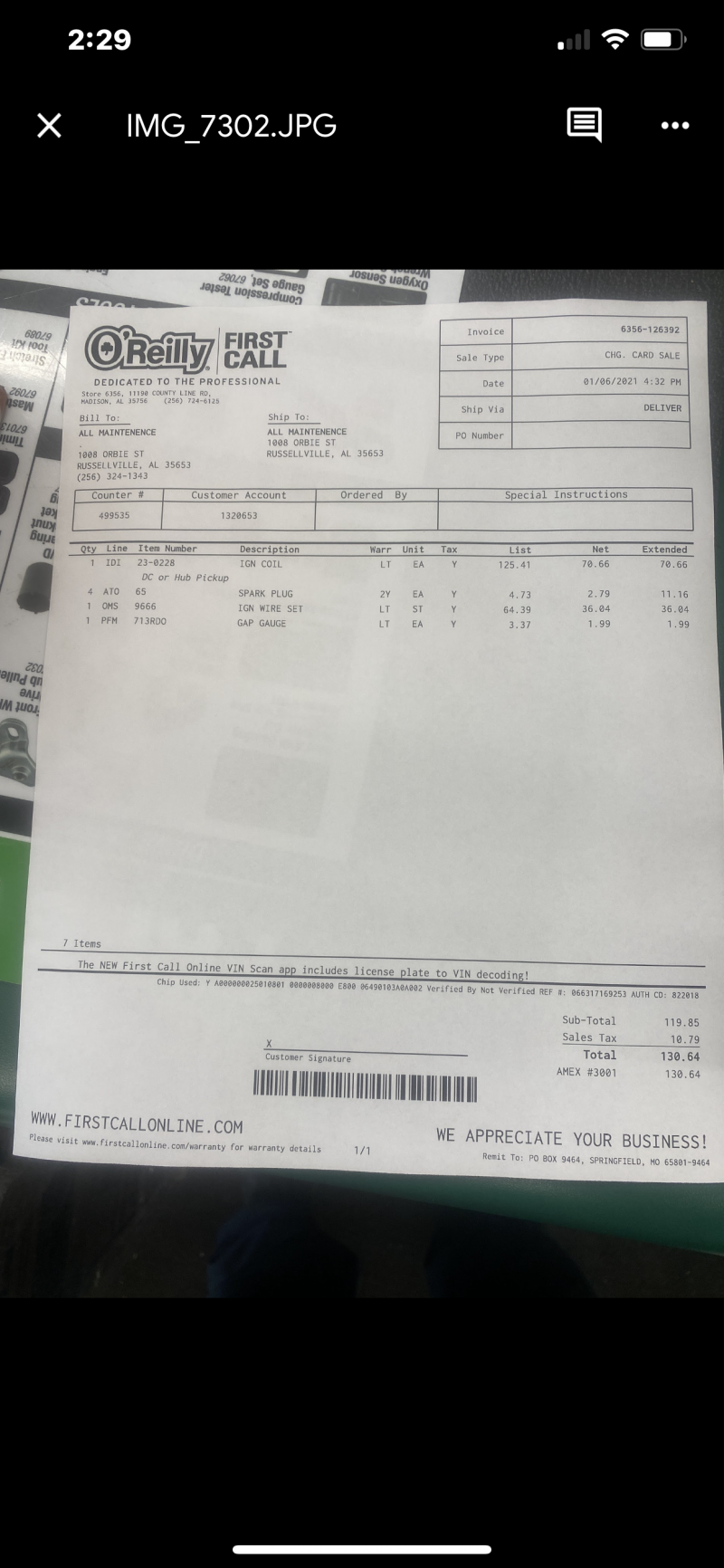

Attached is the part numbers for Orilies . Coil pack, o2 sensor 1 , wires ignition, plugs , secondary o2 sensor. If you get a problem missing or stumble try wires and plugs first .Did you ever find out where to get parts for that engine. I think my new to me thermal wave 2 has that same engine and I might need parts in the future.

Thank youAttached is the part numbers for Orilies . Coil pack, o2 sensor 1 , wires ignition, plugs , secondary o2 sensor. If you get a problem missing or stumble try wires and plugs first .

View attachment 107612 View attachment 107613 View attachment 107614 View attachment 107615

I have the same readings with the fuel pressure at 32psi and the spark plugs are showing very lean burning and the exhaust manifold pipes are glowing red. did you ever find a way to bring it up to the 41-47psi? I've replaced everything except the fuel manifold which will be here in a couple daysThe lines look ok. I just installed a fuel pressure gauge and it’s 32psi at the fuel manifold. The manual says should be 41-47 psi. I ran the machine with the fuel gauge the engine ran fine for fuel pressure held steady at 32 psi. The machine started to bog as usual after 15 min the fuel pressure held steady at 32 psi. Video attached of the bogging