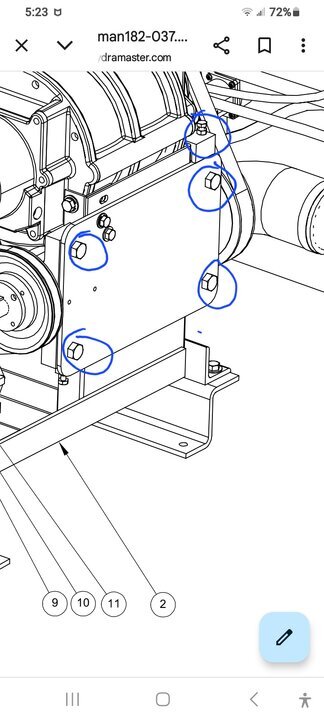

Someone told me that you have to remove a pulley to get the

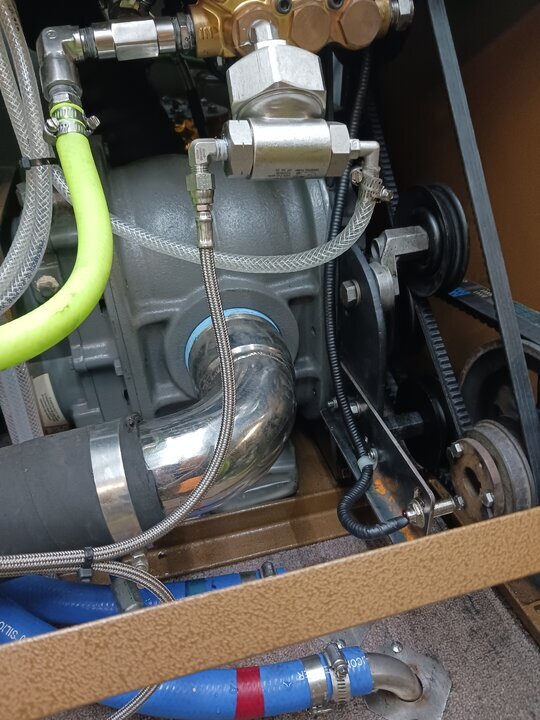

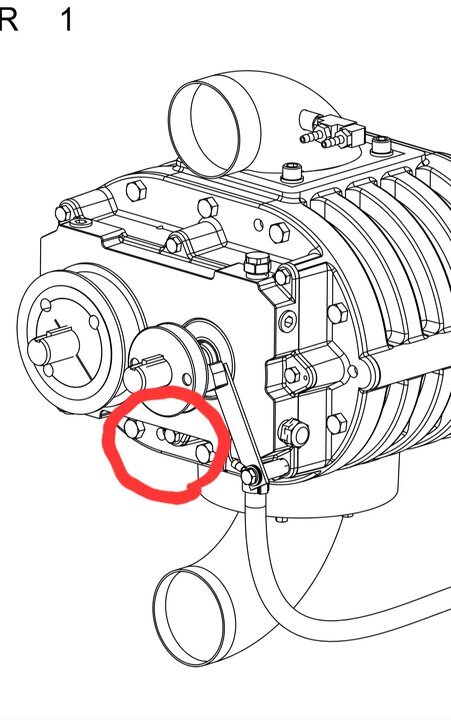

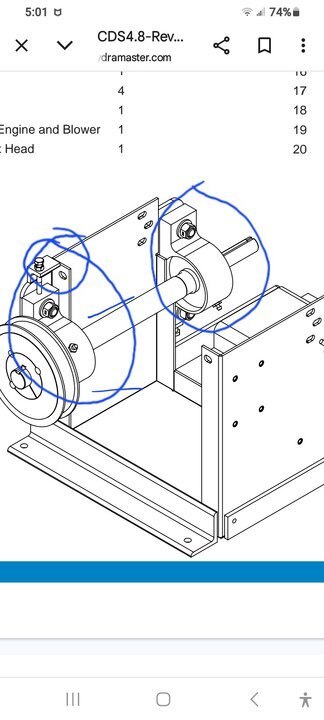

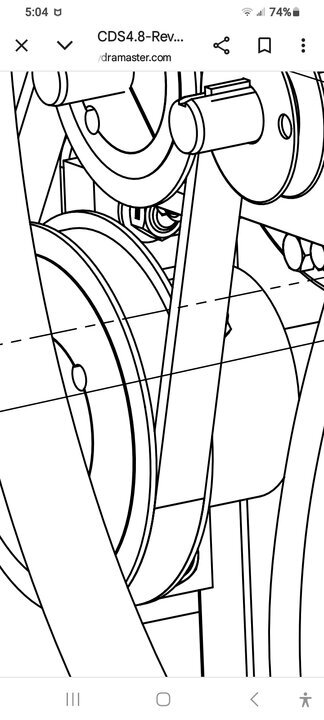

That sure did snap off. About my blower, someone told me that removing the pulley is how to remove the belt, and that somehow the pulley can be adjusted for tension and alignment once it is off. Replacing the belt by removing the pulley seems like the path of least resistance. It is a taper fit pulley with a split collar, I think that will be easy enough. I am looking for a manual for my blower as I'm sure it would say something about adjusting it for tension and alignment it. My blower is a Tuthill 4007-22R3-7963 model. Interlink shows it as the Tuthill 4007x blower on their site. The only dang manual I can find is for a Tuthill CP series 4007 blower, which is blue (mine is black), has only 1 shaft (mine has 2 shafts), and seems too different. The

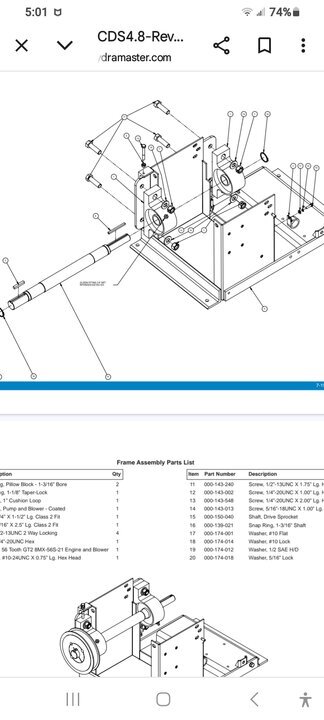

Hydramaster CDS 4.8 manual says they send people a CD that is the appropriate Tuthill 4007 manual when they purchase the machine. Coming up dry everywhere I am looking for it...