BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,552

- Name

- Matt w.

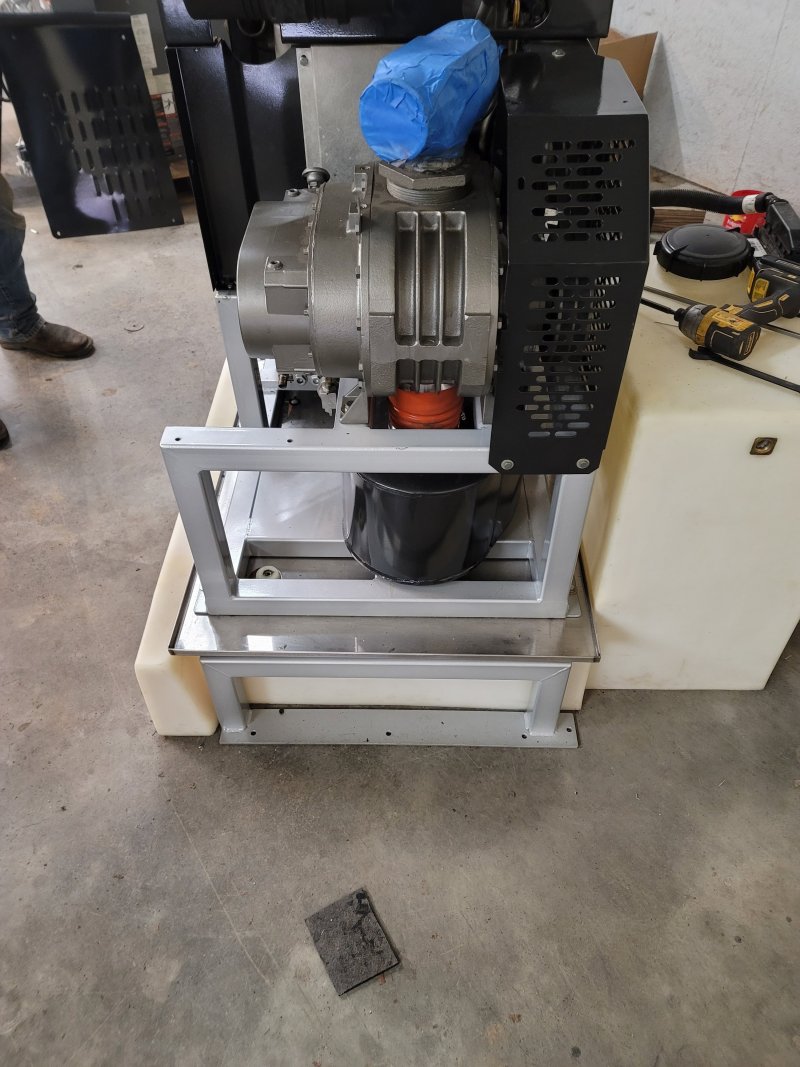

I’m taking it to the forklift later this week to move it. Rubber mats underneath are getting pulled up.

The waste tank was behind it but I think I’m gonna move it to the left side of the machine for better mounting space and ease of access to the rear and right side of the machine.

The van needs a power steering fluid reservoir, a tuneup, and a new rear door

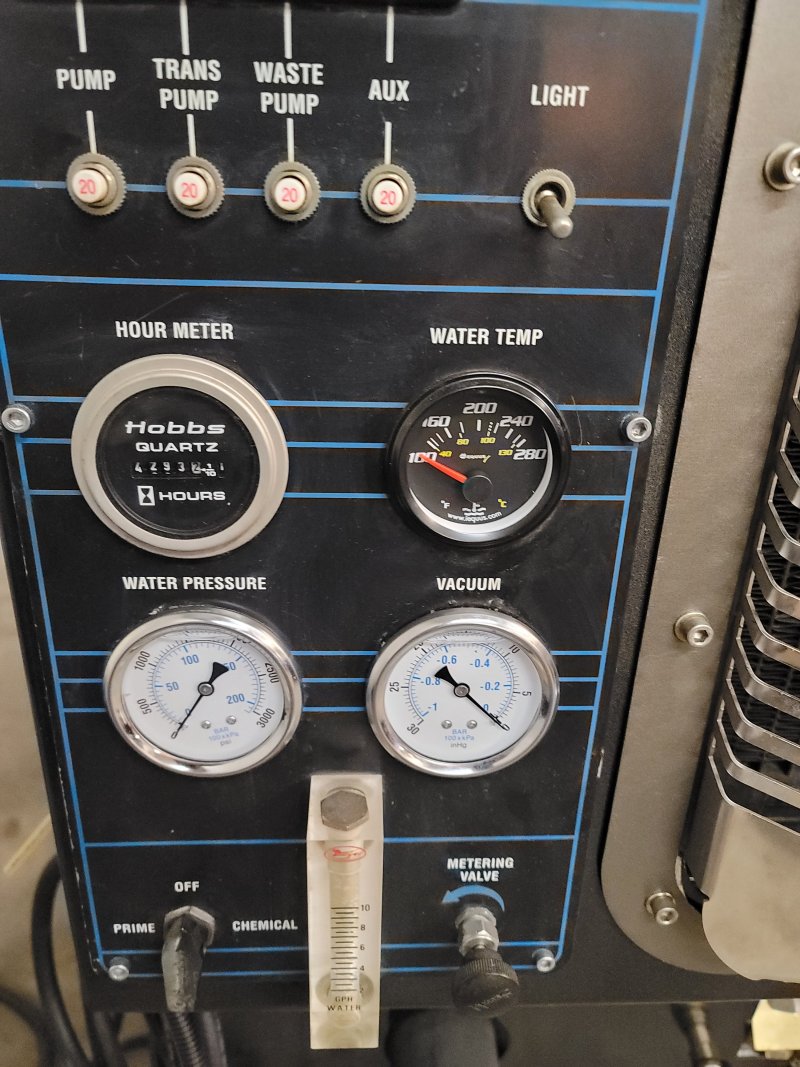

As for the tm, the water pump needs tlc, and the 185f thermal relief valve needs replaced. . Once I get it completed, we’ll see what other issues it might have

. Once I get it completed, we’ll see what other issues it might have

The waste tank was behind it but I think I’m gonna move it to the left side of the machine for better mounting space and ease of access to the rear and right side of the machine.

The van needs a power steering fluid reservoir, a tuneup, and a new rear door

As for the tm, the water pump needs tlc, and the 185f thermal relief valve needs replaced.