BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,583

- Name

- Matt w.

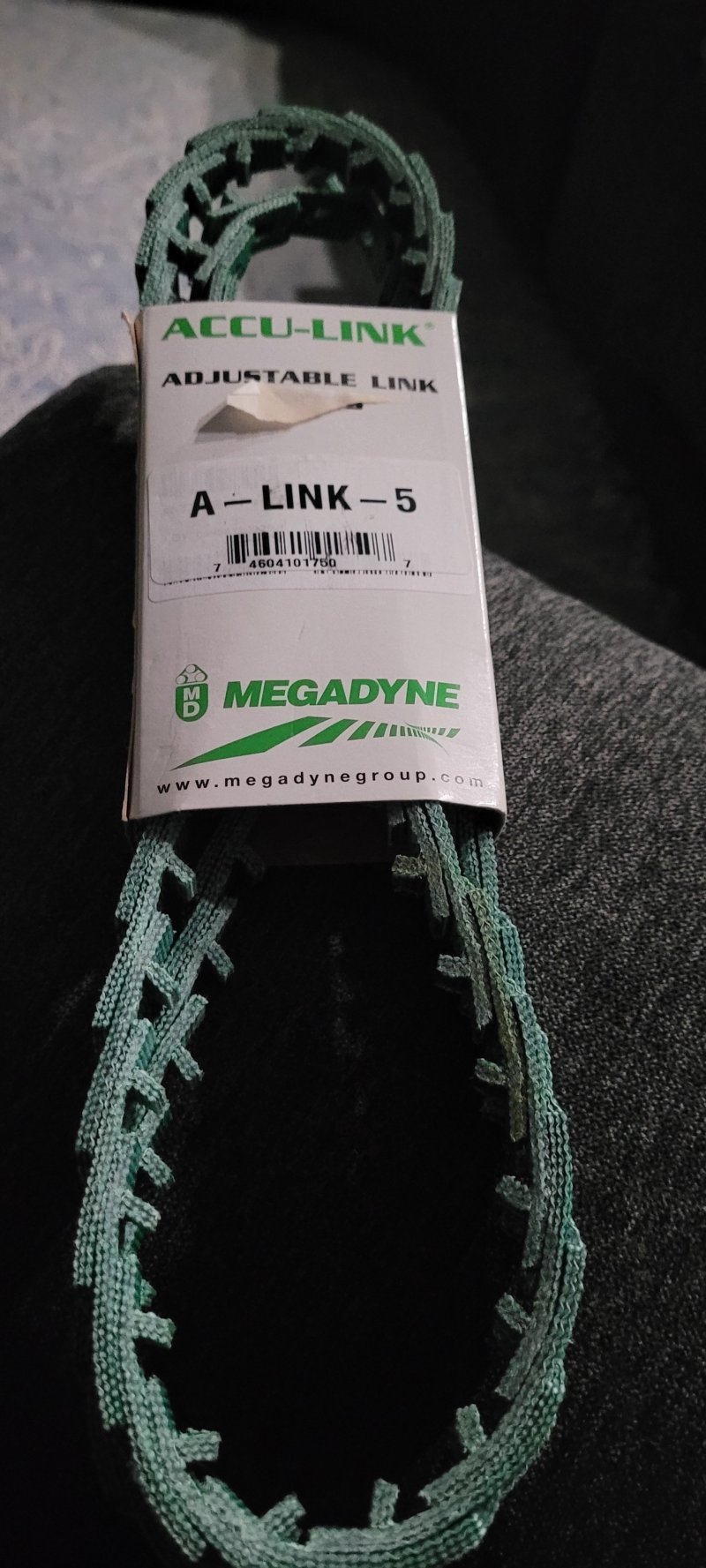

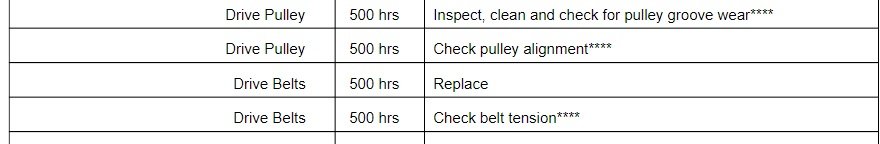

Does the blower on your Butler have grease ports for you to grease the bearings or is it similar to mine?Matt, you say that machine was a demo. That means they probably ran it for an hour then parked it for weeks at a time. Condensation does get inside and causes corrosion which tightens the tolerances up. Probably why it's always been an issue. My butler will bog down too if I don't keep it cleaned and lubricated. I always notice better airflow too after and tge belts last longer. Part of why ibfeel so strongly about this. Get a can of liquid wrench lubricant and squirt the heck out of it. It runs cooler too. It helps break the rust and carbon off. I've watched it come out of the exhaust. It's a performance issue.

And your comment on it being a demo. I think this model was put out in 2016 and I purchased it in 2019. And since it was a demo it did sit for 3 years during the 30hr usage. Your explanation of the corrosion building up makes the most sense. I"ll dig for some more info on this later. Thanks for mentioning this