BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,583

- Name

- Matt w.

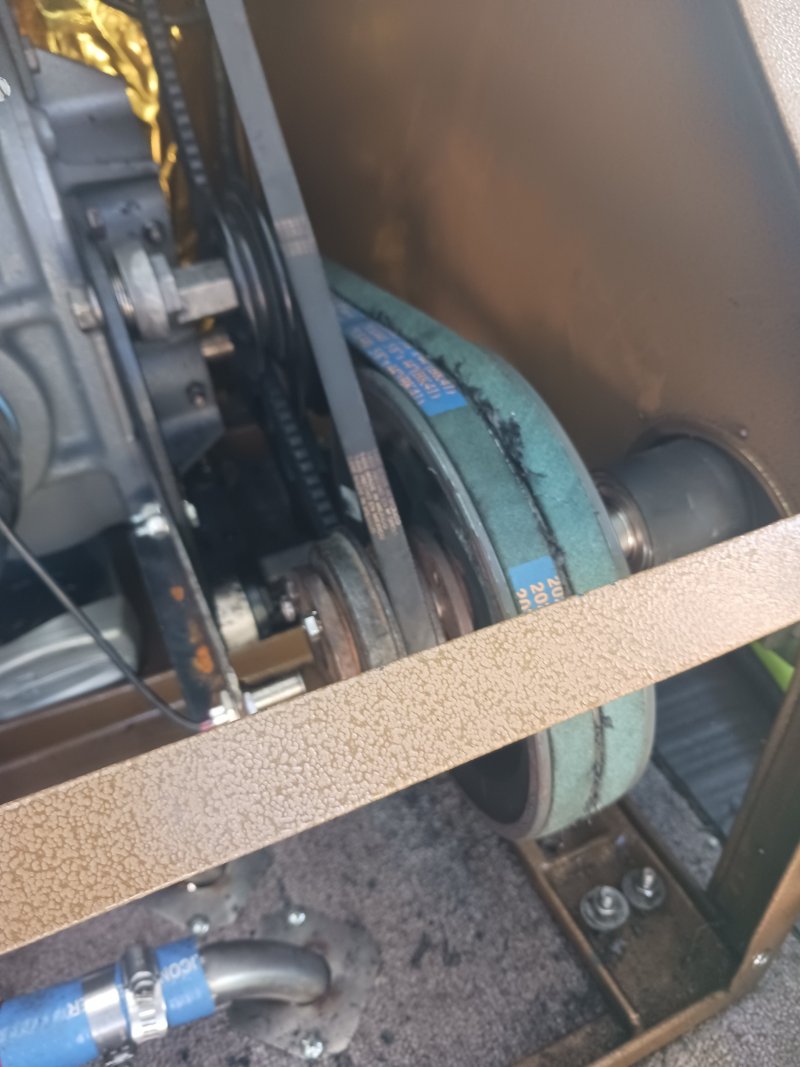

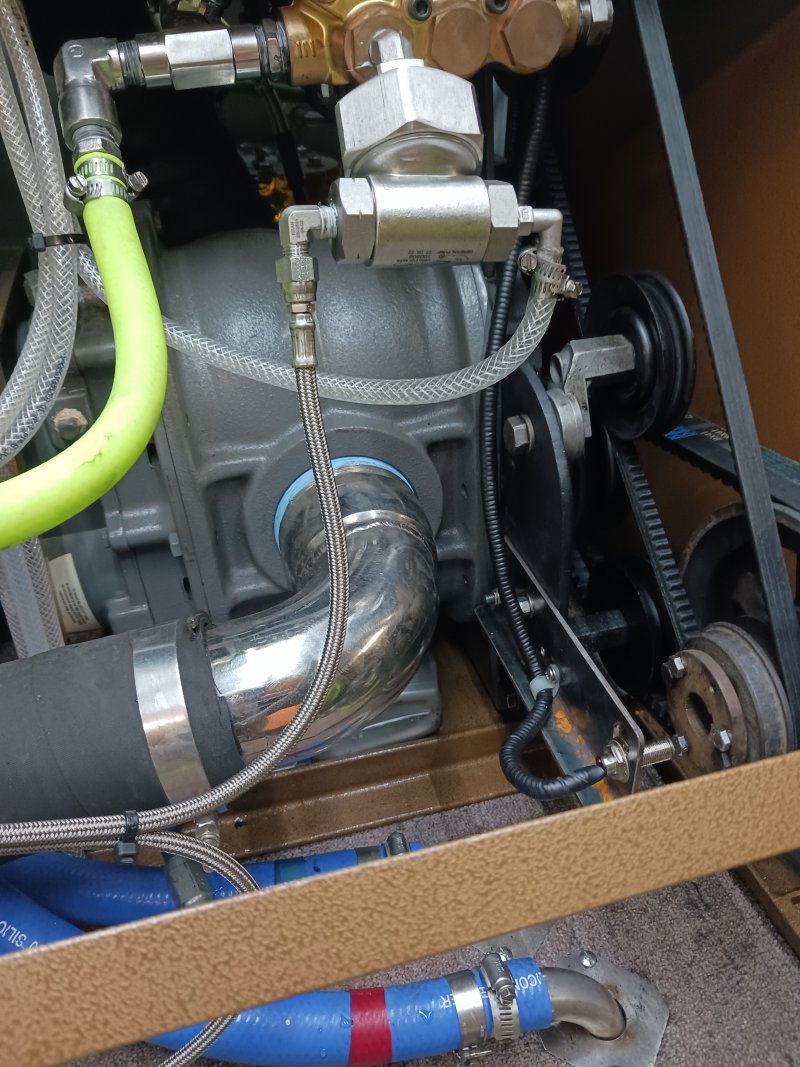

I'm a just a bit stressed at the moment. Beginning of last week my TI-410 blower was starting to lock up, causing my engine to bog down real bad, stretching the belts, making them smoke. I had 2 mechanics check the engine just to rule that out, and it's fine.

History of the blower for the previous 2700hrs:

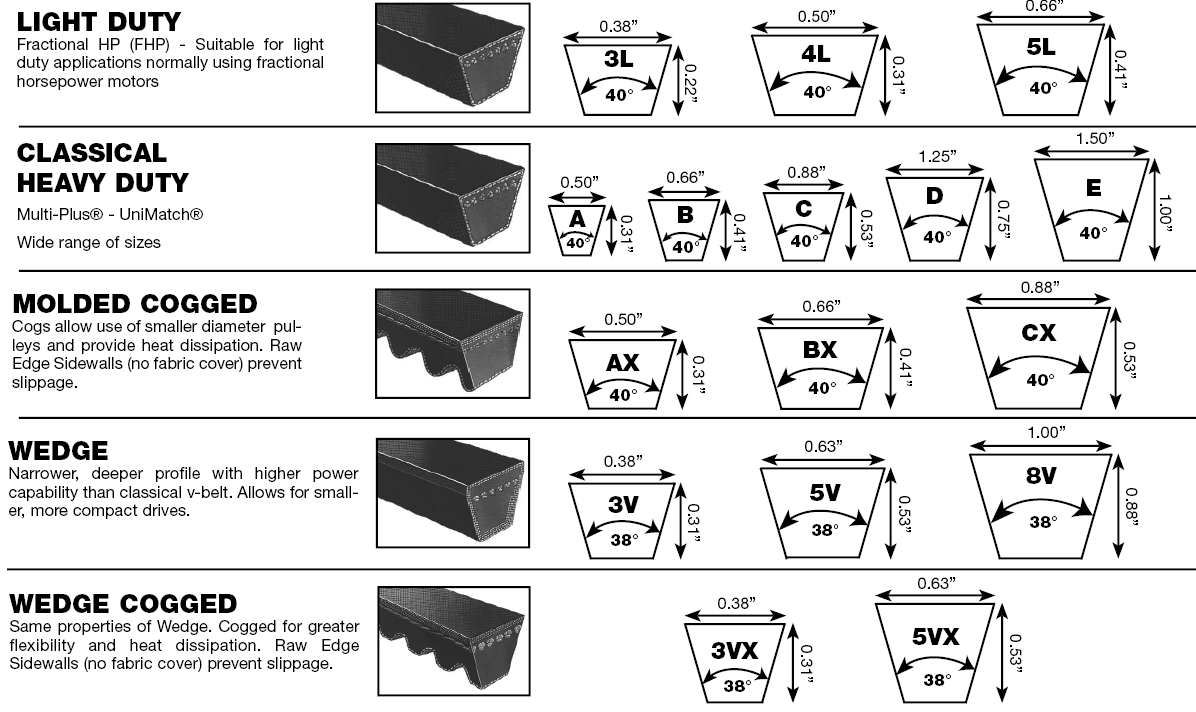

-It loved eating the belts every 300-500hrs, not normal. I see that now. I kept changing them out, thinking it was something I was doing wrong, or thinking it might've not liked the Gates belts.

-Last Summer, the oil seal blew

- I was religious at changing the oil and preventative maintenance.

History of the TM:

-I bought it "new". I'm the only owner, except it being a "demo" with 30hrs on it.

I suspect this blower has had a defective bearing from the manufacturer with the headache of going through belts. Warranty is out and JD isn't giving any support. Matter of fact, when I discussed possibly setting up an appt, the service dept told me to make certain the COUPLER is lined up perfectly if I do it. IT'S BELT DRIVEN! From the last BIG MISTAKE they made at the 2k hr service last year, they lost my business.

Do you think I'm correct on this being defective?

History of the blower for the previous 2700hrs:

-It loved eating the belts every 300-500hrs, not normal. I see that now. I kept changing them out, thinking it was something I was doing wrong, or thinking it might've not liked the Gates belts.

-Last Summer, the oil seal blew

- I was religious at changing the oil and preventative maintenance.

History of the TM:

-I bought it "new". I'm the only owner, except it being a "demo" with 30hrs on it.

I suspect this blower has had a defective bearing from the manufacturer with the headache of going through belts. Warranty is out and JD isn't giving any support. Matter of fact, when I discussed possibly setting up an appt, the service dept told me to make certain the COUPLER is lined up perfectly if I do it. IT'S BELT DRIVEN! From the last BIG MISTAKE they made at the 2k hr service last year, they lost my business.

Do you think I'm correct on this being defective?