BIG WOOD

The Timminator

- Joined

- Feb 4, 2016

- Messages

- 14,502

- Name

- Matt w.

Can all of you, engineers just use the good quality points of all the models to create a machine that doesn't Fk UP after only 2k hrs? Let's start with the information I've put together on the 6 truckmounts that I've owned and maintained that each had it's own positives and negatives

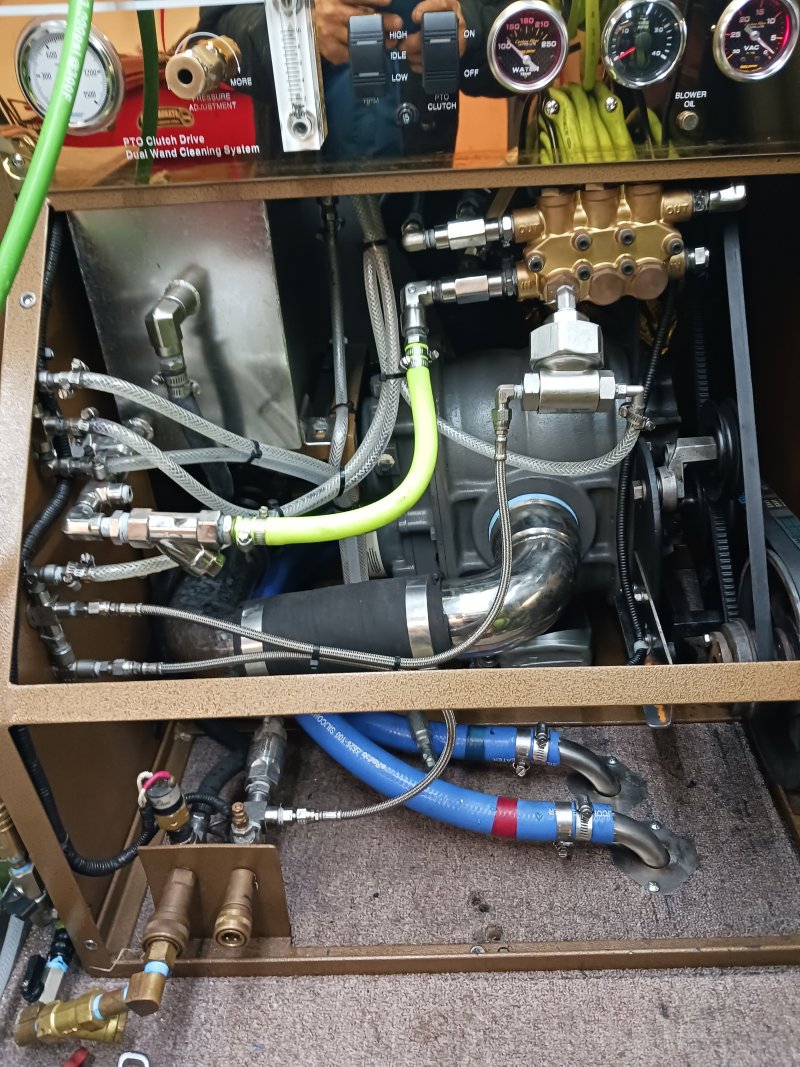

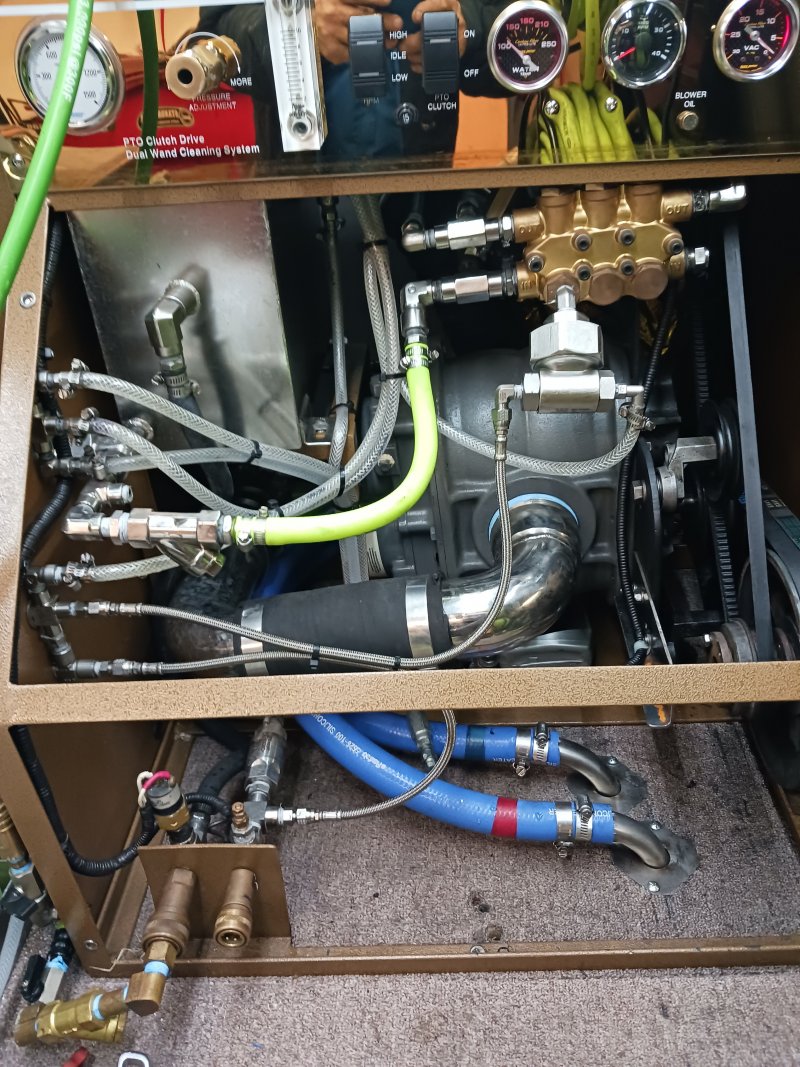

1. Turn that motor sideways to get easier access to the timing belt, blower and blower belt, and put a belt tensioner pulley on all your blowers. Quit using a mounting plate to slide the blower. It's a BITCH to loosen the bolts and it can lead to improper tightening, shrinking of the flex exhaust hose underneath if the blower is moved too far over and a tensioner pulley keep everything straight and the blower breathes so much better. You're completely ignorant if you don't put this feature back into your designs on ALL of your sizes.

2. An external water box is needed to help keep the water from overheating. I've been using a 570 lately and I remember how hot the water was on the amtex, and the water is not maintained as well as the water on my everest, thermal wave, titan, and boxxer XL, and legend was. Sure, it saves space, but so does the way your blowers on the 570 and 370 is set up for it to be a Bitch to adjust on those as well. Saving space shouldn't be your only objective. Ease of maintenance and safety should be your two main objectives. I love how the external water box is mounted on the waste tank and not on the machine.

3. I love the belt coolant system you have on the 570. Incorporate that design in every machine.

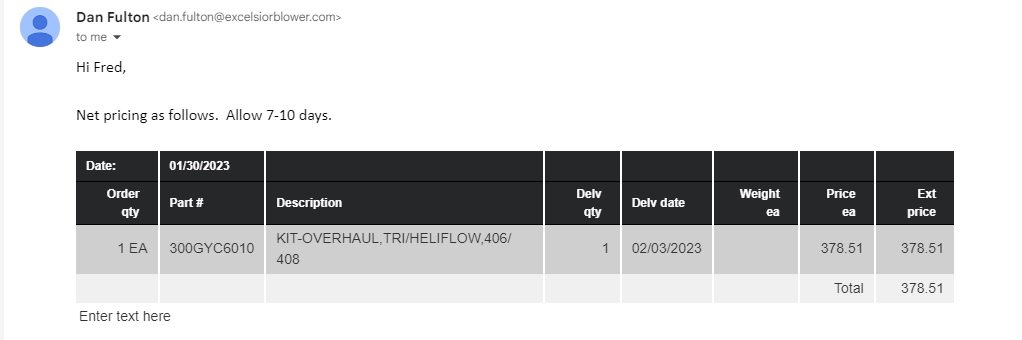

4.Be sure whatever engine you use isn't gonna get discontinued. Same thing with the blowers. I was considering getting a rebuild kit for my TI410, but they were a year out on back order. Douchebag move you guys pulled on that.

5. Hydramaster is most guilty on this: Make a better waste tank. Your tank is a joke. Thin gauge metal, plastic 2" vacuum connections. Look at what the other tanks are made of and how the ports are part of the tank, not screwed in the tank. And your 575 is weak on long hose runs. Both from the design of the waste tank and blower. If you can't make a design that's able to handle 14" instead of your 12" requirement, you're over promising and under delivering a quality product. El-diablow...your waste tank looks very similar. You might want to start getting feedback on that. Hot water is a small piece of your design

6. Electronically: I'm sure you guys already have addressed this, but the ECU needs to be nowhere near that engine. In fact, it should be in a chamber similar to the old prochem machines where they had that chamber in front of the engine where fresh air came in.

7. And quit putting parts on there that get discontinued. That's a dickhead move, knowing that an owner operator like myself being the only source of income for my family could crumble if my GM engine doesn't last much longer from the way it overheated from this computer going bad AFTER YOU installed it right next to the engine block in a CONFINED (look at the side covers), low air moving spot.

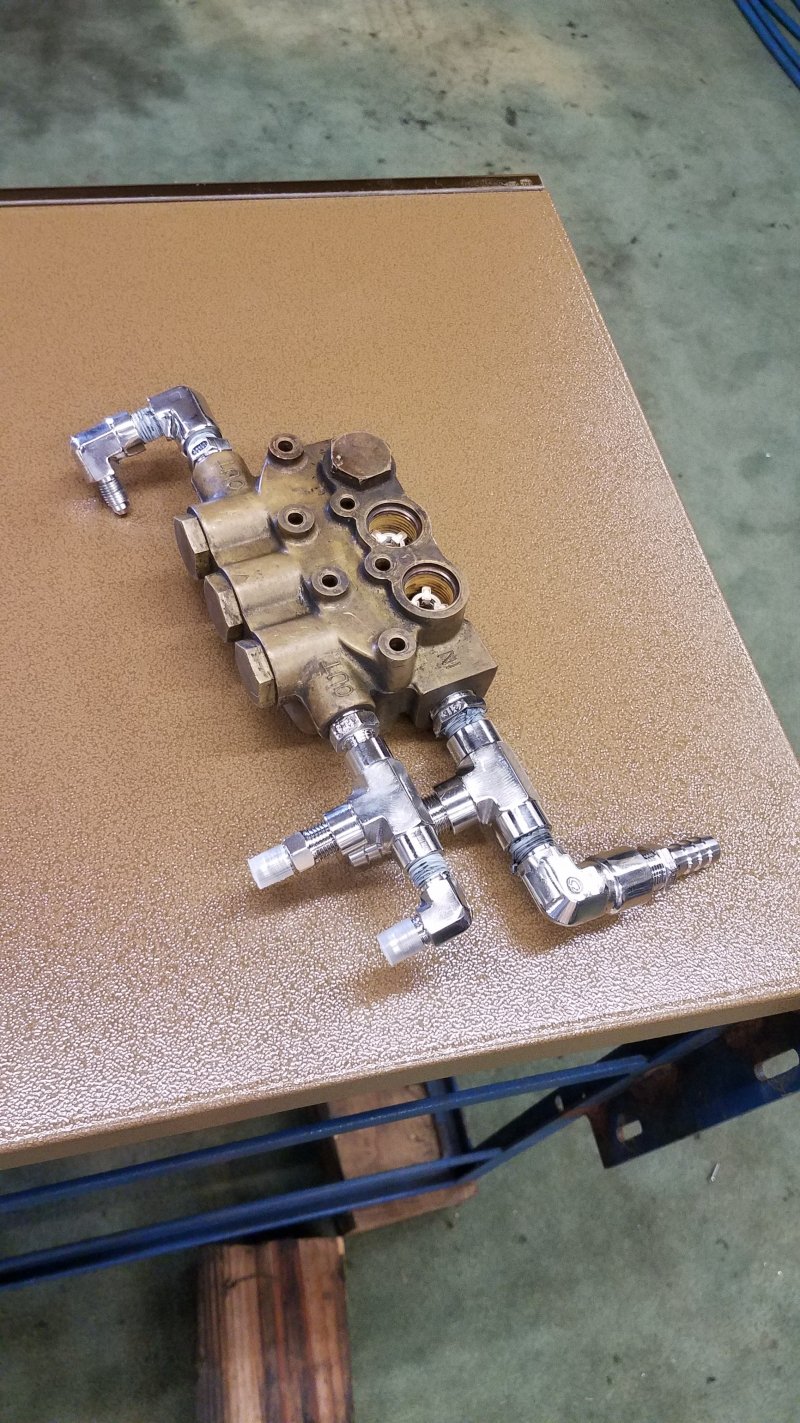

8. And it shouldn’t be the operators job to install a good water filter on the supply side of the machine. It needs to be part of the plumbing.

I go over my machines very frequently and take care of my stuff, only to get more downtime than these big franchises who have freaking losers neglect their machines.

If you can't apply and learn from both your mistakes and improvements and feel like the "latest and re-engineered" is the only avenue, I'm gonna sell out all my machines and go straight with Butler or Aerotech and not do any business with these types of companies.

I was in a conversation with one of the manufacturers this week, and told him of my current headache. His response: "When it rains, it Pours". Well, it would be sunny had they used common sense in these machines before putting them out in the field.

I'M TIRED OF DOWNTIME FROM FAULTY DESIGNS!

1. Turn that motor sideways to get easier access to the timing belt, blower and blower belt, and put a belt tensioner pulley on all your blowers. Quit using a mounting plate to slide the blower. It's a BITCH to loosen the bolts and it can lead to improper tightening, shrinking of the flex exhaust hose underneath if the blower is moved too far over and a tensioner pulley keep everything straight and the blower breathes so much better. You're completely ignorant if you don't put this feature back into your designs on ALL of your sizes.

2. An external water box is needed to help keep the water from overheating. I've been using a 570 lately and I remember how hot the water was on the amtex, and the water is not maintained as well as the water on my everest, thermal wave, titan, and boxxer XL, and legend was. Sure, it saves space, but so does the way your blowers on the 570 and 370 is set up for it to be a Bitch to adjust on those as well. Saving space shouldn't be your only objective. Ease of maintenance and safety should be your two main objectives. I love how the external water box is mounted on the waste tank and not on the machine.

3. I love the belt coolant system you have on the 570. Incorporate that design in every machine.

4.Be sure whatever engine you use isn't gonna get discontinued. Same thing with the blowers. I was considering getting a rebuild kit for my TI410, but they were a year out on back order. Douchebag move you guys pulled on that.

5. Hydramaster is most guilty on this: Make a better waste tank. Your tank is a joke. Thin gauge metal, plastic 2" vacuum connections. Look at what the other tanks are made of and how the ports are part of the tank, not screwed in the tank. And your 575 is weak on long hose runs. Both from the design of the waste tank and blower. If you can't make a design that's able to handle 14" instead of your 12" requirement, you're over promising and under delivering a quality product. El-diablow...your waste tank looks very similar. You might want to start getting feedback on that. Hot water is a small piece of your design

6. Electronically: I'm sure you guys already have addressed this, but the ECU needs to be nowhere near that engine. In fact, it should be in a chamber similar to the old prochem machines where they had that chamber in front of the engine where fresh air came in.

7. And quit putting parts on there that get discontinued. That's a dickhead move, knowing that an owner operator like myself being the only source of income for my family could crumble if my GM engine doesn't last much longer from the way it overheated from this computer going bad AFTER YOU installed it right next to the engine block in a CONFINED (look at the side covers), low air moving spot.

8. And it shouldn’t be the operators job to install a good water filter on the supply side of the machine. It needs to be part of the plumbing.

I go over my machines very frequently and take care of my stuff, only to get more downtime than these big franchises who have freaking losers neglect their machines.

If you can't apply and learn from both your mistakes and improvements and feel like the "latest and re-engineered" is the only avenue, I'm gonna sell out all my machines and go straight with Butler or Aerotech and not do any business with these types of companies.

I was in a conversation with one of the manufacturers this week, and told him of my current headache. His response: "When it rains, it Pours". Well, it would be sunny had they used common sense in these machines before putting them out in the field.

I'M TIRED OF DOWNTIME FROM FAULTY DESIGNS!

Last edited:

Don't cry about spilt milk, clean it up and keep on truckin..

Don't cry about spilt milk, clean it up and keep on truckin..